| VISUAL FAULT LOCATOR (VFL) INFORMATION | |

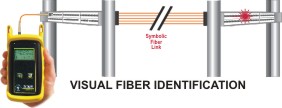

| Visual Fault Locators (VFL) play an important part when working on a fiber optic network, especially installation, testing, and troubleshooting. The bright red laser in a VFL allows for quick and easy near-end visual fault location and visual fiber identification (click examples below for larger images). | |

|

|

|

As an option, the charger port in ZOOM 2 optical power meters can be replaced by a

precision-coupled Visual Fault Locator (VFL). By integrating a VFL into the power meter,

troubleshooting for near-end faults can be done on the spot during testing.

OWL precision-coupled VFLs offer two distinct technological advantages over traditional laser pen-style visual fault locators. First, a multi-million dollar micro-alignment machine is used to place a tiny ball lens between the laser diode and the output port, allowing for optimum precision-coupling of optical power into both multimode and singlemode fibers. Second, red lasers are susceptible to burnout, which is typically caused by power surging from the battery when the unit is powered on, especially from new batteries. Over time, these battery surges can weaken the laser, significantly limiting the laser's effectiveness. OWL optical power meters contain special circuitry that protects the red laser diode from battery power surges, ensuring a stable and consistent source of red light as well as maximizing the life-span of the laser. CLICK HERE TO RETURN TO THE ZOOM 2 OPTICAL POWER METER PAGE. |

|