| VOLT (VISUAL OPTICAL LENGTH TESTER) | |

| Almost all fiber optic experts own a VFL similar to VOLT but they don't get

the extra benefit length testing features of VOLT !

VOLT functions as any good quality Visual Fault Locator (VFL). However, with the same price range as other VFL's VOLT has the added benefit of doubling as a LOOPING length tester! Many cabling warranties and bids are requiring meter based length tests to prove length of links. VOLT uses 2 fibers and patch cables to establish a length test accurate to +/- 7 feet ! VOLT's VFL functions up to 5 Kilometers (3.1 Miles). Loop length testing functions up to 1.5 Kilometers. As far as VFL function, VOLT holds its own against the best in the industry. As with any quality VFL VOLT is a precision coupled laser diode! VOLT is not made as a cheap laser light pen is designed! Rather, a multi-million dollar semiconductor machine is used in the manufacture of a special precision coupled micro sized ball lens. This precision coupling allows VOLT to couple maximum red laser light into the tiny connector orifice of fiber optic links up to 5 Kilometers (3.1 Miles) of distance! |

|

| Pricing | ||

| Part # | Description | Price |

| VOLT-1 |

Visual Optical Length Tester (VOLT)

|

435.00 |

| OPTICAL LENGTH MEASUREMENT |

KEY BENEFITS

|

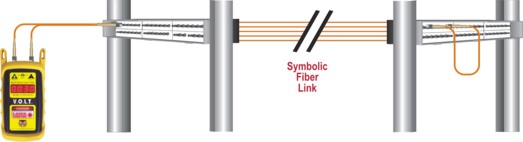

Example: fiber link length measurement |

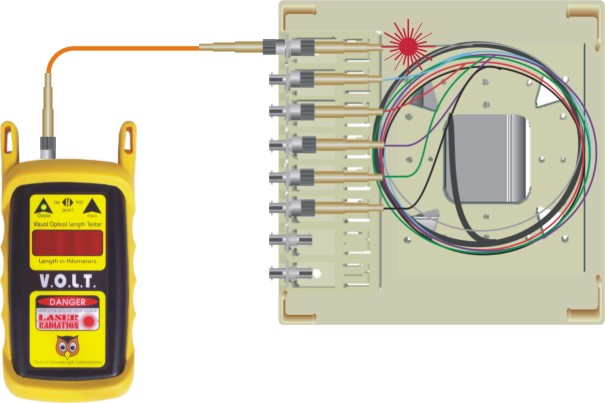

Example: visual fault location |

| Also functions as a visual fault locator up to 5 Kilometers and measures length of

multimode or singlemode fiber loops up to 1.5 Kilometers!

Most quality VFL's will go this distance. However at extreme distances like this the "fault finding" capability is reduced to fiber identification only. At shorter "LAN" distances high energy red laser light can be used to see breaks in fiber behind patch panels (hence the name visual fault finder). But be assured VOLT holds its own against any other brand name VFL! Fiber installations are increasingly required to have fiber length measurements to comply with bid requirements. Rather than purchase expensive certification test sets, the VOLT can be added to an installer’s existing fiber test kit for a fraction of the cost. Optical length testers save time by eliminating the need to measure fiber by the cable jacket. Fiber links may also go through multiple cross-connects or have splices in the middle, thereby making jacket markings invalid. Optical measurement of fiber produces accurate results without the need for jacket markings. Optical measurement also saves time by eliminating the need to estimate the length of the fiber run with a measuring wheel. This method is especially troublesome and inaccurate in networks that traverse walls, are in a star topology, or contain riser cables. The VOLT uses a "round-robin" method of measuring fiber length. This is accomplished by looping back two fibers at one end of the fiber run. The round trip time that the light takes to travel through the fibers is converted to length in kilometers, then divided by two to show the length of the fiber cable. There is no need to measure the length of all the fibers; the length measurement can be applied to all fibers in the cable. IMPORTANT: BOLT-NL IS NOT DESIGNED TO FIND DISTANCE TO A FAULT OR REFLECTION. |

| Documents | |

|

VOLT Datasheet

|

VOLT Operations Guide

|

| HELPFUL VIDEOS | ||

VIDEO: replacing the battery |

VIDEO: Cleaning Optical Ports |

VIDEO: Optical Length Measurement Methods |